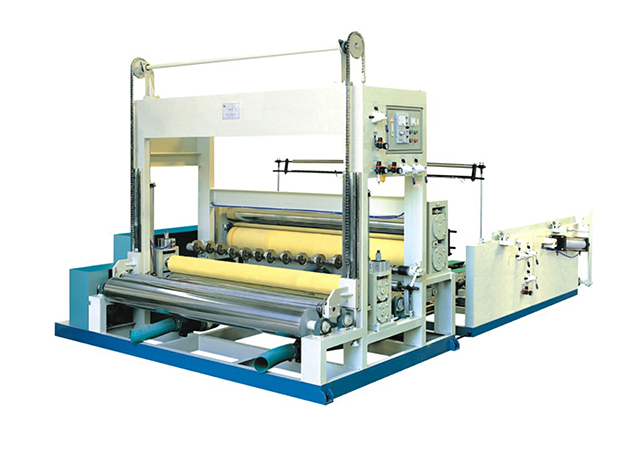

Slitter Machine

PARAMETERS

| Model | 1092 | 1575 | 2000 | 2200 | 2400 | 2600 | 2800 |

| Raw Material Width | 1330 | 1750 | 1950 | 2150 | 2350 | 2550 | 2750 |

|

Finished products diameter |

≤Φ1200 | ||||||

| Slitting Width (mm) | Adjustable | ||||||

|

Material Diametere(mm) |

≤Φ1100 | ||||||

|

Raw material Core Diameter(mm) |

76.2(Other sizes are available) | ||||||

| Speed | 260-300m/min | ||||||

| Unwinding Unit | 1-3layer Can be appointed | ||||||

| Calendering | Steel to Steel or Steel to Rubber(Option) | ||||||

| Pneumatic System |

3HP Air Compressor,Mini Air Pressure5 kg/cm2 Pa (provided by customer) |

||||||

| Power | 4.5-11KW | ||||||

| Dimension(L×W×H) | 6200x2600x1800 TO 6200x4000x1800 | ||||||

| Weight | 3800 TO 7000kg | ||||||

| Option | |||||||

| Rewinding unit | Air-shaft | ||||||

| Transmisson System | Frequency conversion speed regulator | ||||||

MAIN FEATURES:

slitting machine for the slitting and rewinding of tissue, non-woven or air-laid paper and other

PF-A automatic sltting machine is used to slit and rewind the bathroom tissue, non-woven and

air-laid paper materials. The single ply paper can be slit and rewinded into two, three or four ply

paper with various widths, for the production of napkins, hankies, facials or sanitary napkins.

The machine is featured of good performance,compact structure, and stable running, and easy

operation. The finished products have good winding profiles, which make it a good equipment

for the paper mills and textile factories, and a high reputation from the customers. The machine

can be equipped with double calendering rolls .