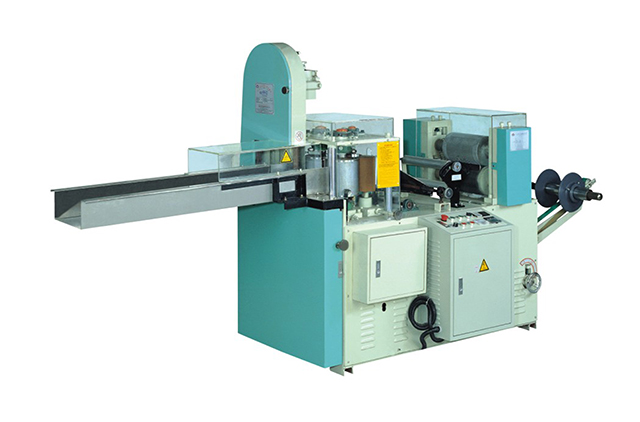

Napkin Machine

PARAMETERS

|

Model |

BS-N-1 |

|

Parent roll width |

Subject to the size ordered |

|

Max. parent roll diameter |

φ1100mm |

|

Core inner dia.of parent roll |

3” (76.2mm) |

|

Parent roll web material |

1-3 plies tissue paper with 18-25GSM each ply |

|

Finished product size |

Subject to the size ordered |

|

Embossing unit |

Steel to rubber/felted/paper roller (steel to steel embosser or Engraved embosser need to be ordered) |

|

Counting |

Electronic / Pneumatic ( to be ordered) |

|

Machine speed |

160-180m/Min. |

|

Folding unit |

1/4 fold ( pls specify if other fold type needed) |

MAIN FEATURES

Napkin folder use to form the well-cut parent roll web into regular Napkin tissue after embossed and folded.

Main features:

1. *With Steel to rubber Calender unit, embossing can be steel to felted roller, paper roller or rubber roller( choose one)

2. After the paper web is unwinding, it will be sent to the calender unit, printing unit then embossing unit. There is manual

adjustment for the paper tension between the unwinding and calender unit and embossing unit.

3. Machine will stop automatically at the paper web wind up the folding roller.

4. The gap between two folding&cutting rollers can be adjustable according to different plies and GSM.

5. *Steel to Steel calender roller can be added on machine.

6. *Engraved embosser can be added on machine.

7. *Automatic constant temperature heating unit on embosser unit can be ordered.