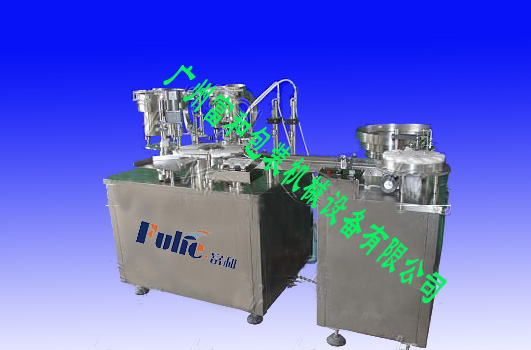

FHGN-2 Filling- Inner Cork -Capping In One Machine

PRODUCT DETAILS

This liquid machine integrates with inner cork, capping, filling , it aim at the vessel of middle size ,and suitable for filling different shape of bottle ,such as roundness , platy , prismatic , especial suitable for the material’s error is bigger which is made in China and all kinds of abnormal shape bottle , inner cork and outer lid. Compare with the foreign congeneric filling machine , the function for the machine has Obvious advantage .Fully embody our advantage in design and manufacture nonstandard products . It is suitable for daily health products, beverage filling, inner cork, outer lid, accord with medicine standard of GME.

OPERATION PRINCIPLE

Putting the empty bottles in the hopper tray, the bottles are sent to screw device by elevator belt ,then the bottles send into the filling host machine one by one . It also bottle feeding by turnplate . Putting the bottles into the turnplate , turnplate will send the bottles to the conveyor , then convey to work in the major turnplate. The sensor detect have bottle or not on the working platform , detection signal will be sent to internal control system, realize that no bottle no filling .

CHARACTERISTICS

1. The machine adopts adjustable piston for fast and accurate volume adjustment.

2. The parts contacting media are made from 316L.

3. Automatic bottles feeding , operate , fixed position, adopt automatic control.

4. Not only working alone but also connect automatic labeler and automatic cartoning machine production line .

5. If you want to change the bottle standard ,just change star wheel , free adjustment high-low .

6. It adopts continuous variable speed piston, The speed of operation is adjustable .

TECHNICAL PARAMETER

| Model | FHGN-2 |

| Filling rate | 40-60b/min |

| Filling volume | 10ml-15ml |

| Filling precision | ≤±1% |

| Voltage | 380,50(V , Hz) |

| Total power | 0.8(Kw) |

| Barometric pressure | 0.5m3/min(MPa) |

| Gas consumption | 0.5m3/min |

| Weight | 550(kg) |

| Overall dimension | 2000mm*1640mm*167mm |